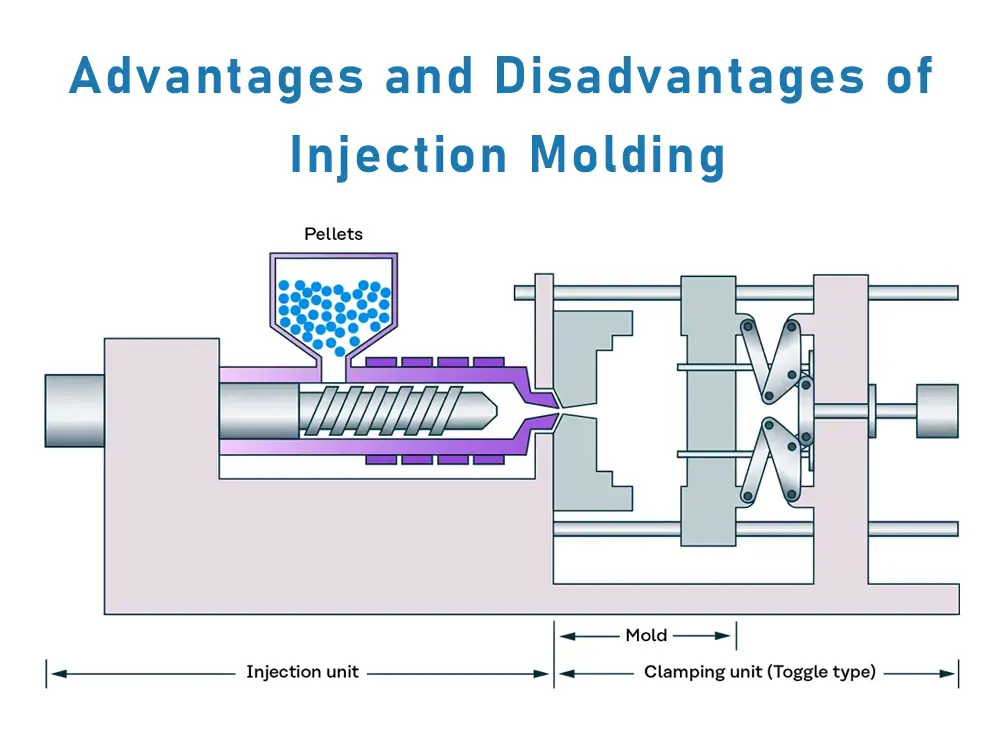

The intricate and complex design of different material products leaves us amazed. For example, you see plastic toys, glass products, and metal equipment. Have you wondered how they are manufactured? Injection molding is the science behind it. However, it is not always a perfect process. There are several advantages and disadvantages of injection molding. …

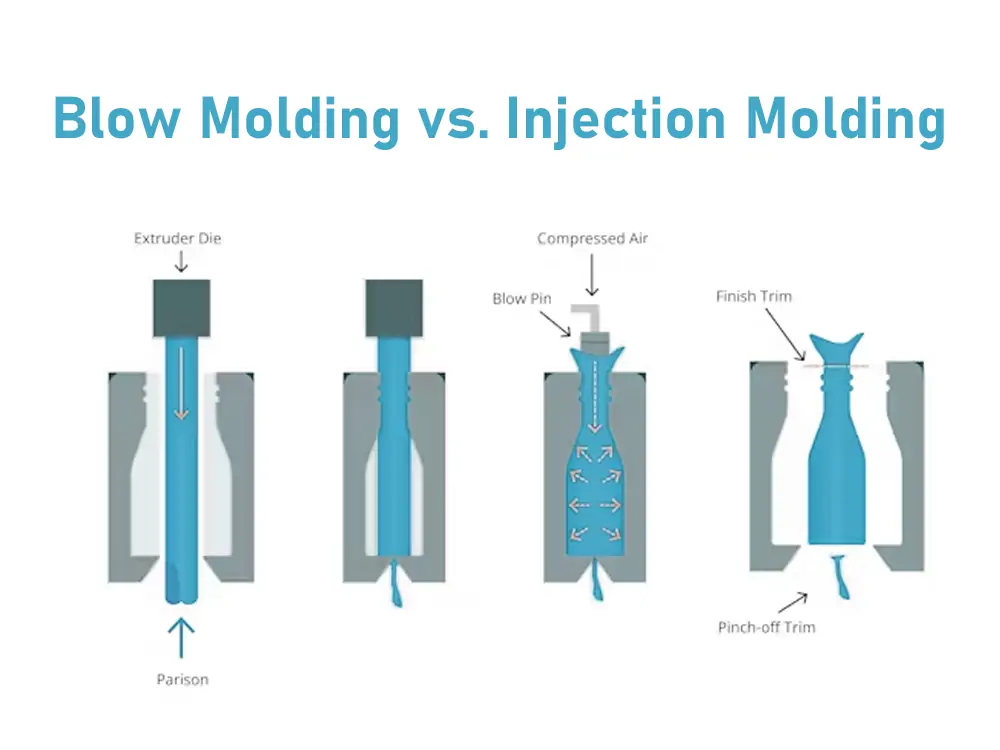

Blow and injection molding are popular high-volume production techniques. Interestingly, both are very cost-effective and offer decent precision. However, there are many differences between these two production methods. Those distinctions lay the foundation of the debate on blow molding vs injection molding methods. As I said, both are convenient techniques for producing plastic products….

Are you looking for the top 10 plastic injection molding companies in the USA? You’re more likely to see tons of options. The American manufacturing market is very diverse. Both newer and well-established companies will welcome you. However, selecting one company among the lot can be super confusing. New plastic injection molding companies lack…

Plastics are one of the most common manufacturing materials. They are versatile and functional. You can literally find it everywhere, from electronics to the aerospace industry. They are available in a variety of shapes and dimensions. But, do you ever wonder how someone shapes plastics and rubber? That’s where the injection molding technique turns a…

On August 26, 2024, the boss of KEEN, a leading sports shoe brand, came from the United States to visit the Cambodian factory. Before this, Keen’s Cambodian factory purchased our latest fully automatic rubber injection molding machine in its Cambodian factory. This cooperation marks another important breakthrough for TASU in automated production and further consolidates…

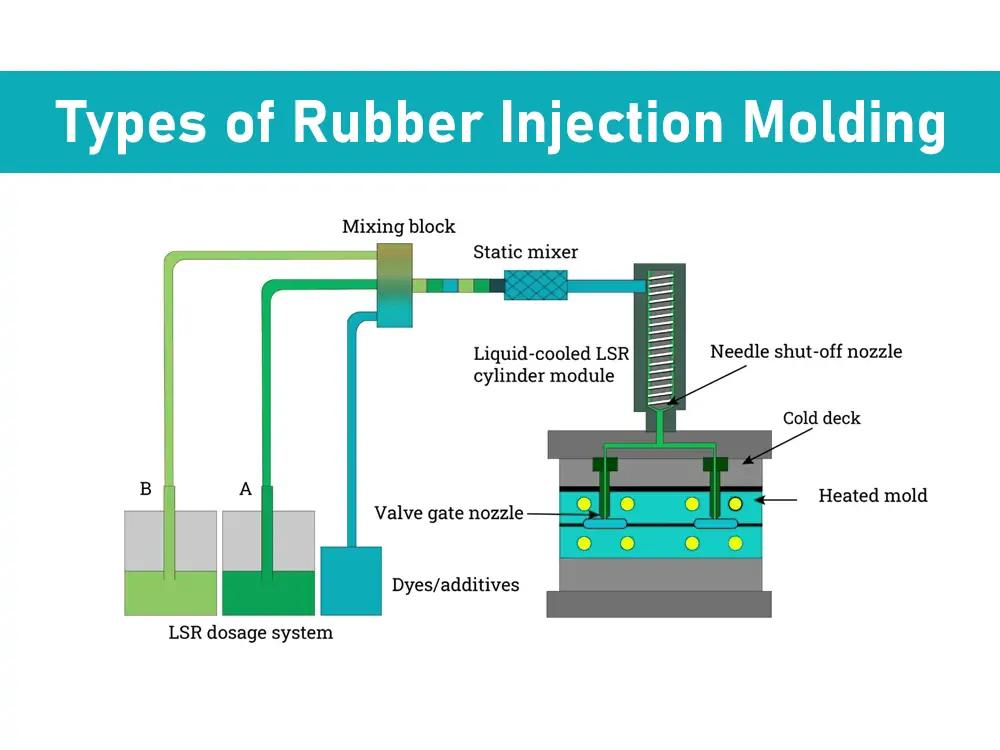

Rubber products are commonly used in routine life. They are all the result of the rubber molding process. Interestingly, there are different types of rubber molding processes. Each of those varies in terms of how it produces the final products. Some of those types are suitable for creating bigger-sized products. Similarly, some molding processes…

The hydraulic molding machines are the oldest. They have been used for many decades to produce different parts. However, the electric machines are relatively newer. These two machines have many differences. Their distinctions give rise to a debate on electric vs hydraulic injection molding machines. Some old-school people consider the hydraulic system as the…

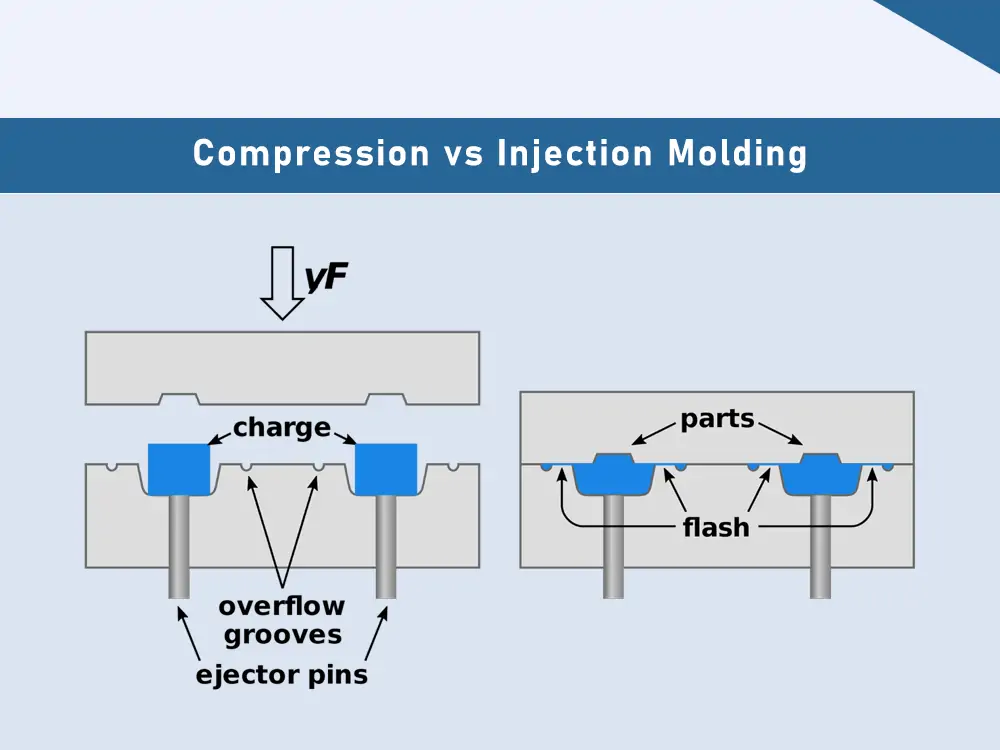

Nowadays, plastic and rubber products are predominant. Several production methods produce these products. However, compression and injection molding are the most popular methods. Some people consider the compression process more favorable, while others prefer injection molding. This debate led me to write about compression vs injection molding. These two molding methods vary in many…

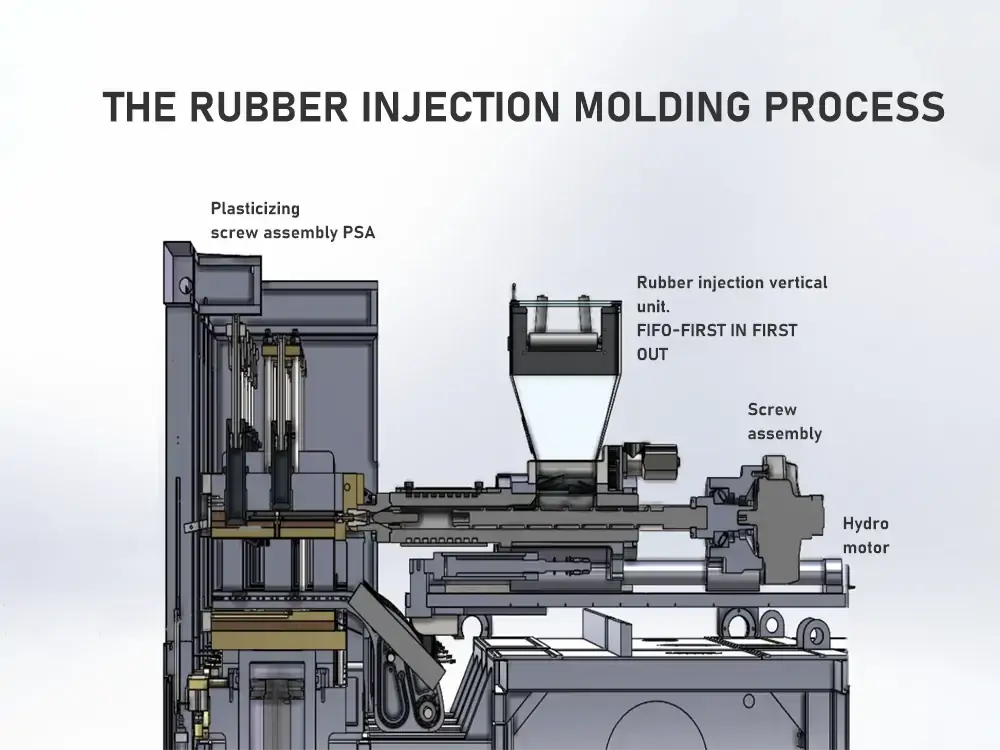

The rubber injection molding process has brought massive change. It has given a new way to create accurate products quickly. You can make thousands of rubber products using this manufacturing method. It is a cost-effective solution that helps achieve 100% precision. Everyone knows this process uses specialized injection molding machines. But no one knows…

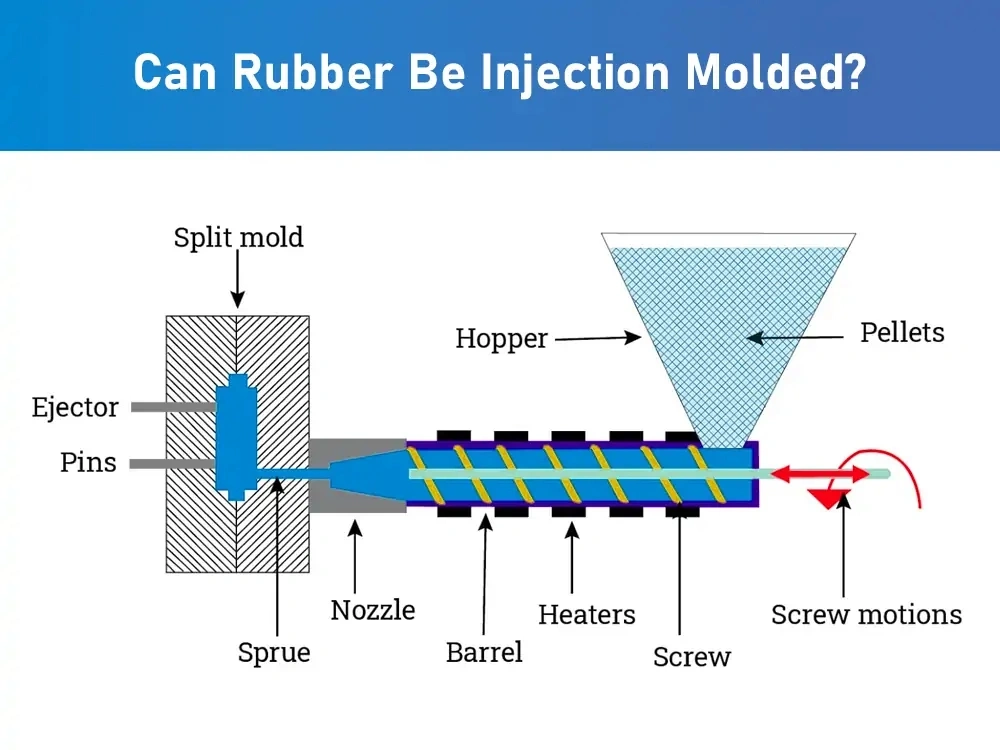

Rubber is a popular material used in making various products. Its elasticity, strength, and inexpensiveness make it stand out. This material can easily undergo different manufacturing methods to create numerous products. However, many people feel confused when it comes to injections. So, they question: Can rubber be injection molded? Remember, rubber does not melt…

- 1

- 2