Rubber is a popular material used in making various products. Its elasticity, strength, and inexpensiveness make it stand out. This material can easily undergo different manufacturing methods to create numerous products. However, many people feel confused when it comes to injections. So, they question: Can rubber be injection molded?

Remember, rubber does not melt as smoothly as plastics do. However, injection molding involves the melting of the material. This limitation raises questions about rubber’s usability in the injection molding process. Moreover, rubber has many types. So, can all of those types be injection molded? Don’t be confused! This article will answer all the questions.

Overview of Injection Molding

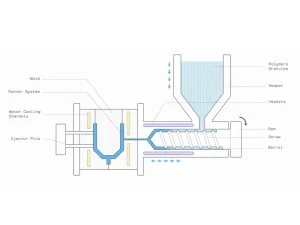

Injection molding is a production process that utilizes molds. The molten material is filled in these molds, similar to the shape of the product we need. The molten material inside the molds solidifies and adopts the mold’s shape. Later, these molded products are ejected from the molds.

In the previous guide, I explained everything related to the injection molding process. This production method is straightforward and less costly. All you need is a rubber injection molding machine, and you’re ready. Remember, different types of materials are used in these injection molding machines.

In this method, the material undergoes extreme heating and melting. Remember, this method produces products after melting the material. A material with a very high melting point would not be suitable for injection molding. Manufacturers generally prefer using plastics and rubber in the injection molding process.

Both of these materials have different properties. Not to forget, the rubber itself has many other types. For example, some are natural rubber extracted from the sap of trees. Conversely, some are synthetic, which means they are artificially made from chemicals. This section below will discuss their compatibility with the injection molding process.

Can Rubber Be Injection Molded?

Yes, rubber can be used for injection molding. Rubber is already soft and elastic. Heating this material further increases its softness. Although rubber does not melt smoothly, its softness resembles that of its molten state. So, it can be filled in the molds and used in the molding process.

The primary issue is that the rubber does not melt as the plastics do. For example, when you melt plastics, they change into molten form. Filling this molten material into molds is easy. But that’s not the case with rubber. Instead, upon heating, rubber softens and becomes viscous instead of melting.

But that’s not an issue as this soft material can be filled into the rubber. Both organic and synthetic rubber can be used in molding. Remember, the filling of such viscous rubber material is not straightforward. Moreover, this viscous rubber takes more time in molds to solidify. Simply put, rubber injection molding is possible, but it makes the process a bit slower.

So, do manufacturers use rubber in injection molding despite its drawbacks? Yes, rubber is one of the most prominent materials in injection molding. Remember, manufacturers use optimal temperature and pressure to cope with its challenges. It is a low-priced and readily available material, which enhances its value.

Quick Highlight: Each type of rubber exhibits unique properties. So manufacturers use them as per their needs and requirements. Moreover, the molding process of each of those types is also not the same. As far as this question is concerned, yes, rubber can be injection molded.

Types of Rubber that Can Be Injection Molded

As I said earlier, there are different types of rubbers available. The most prominent types are natural and synthetic rubbers. Both of these types can undergo injection molding. These two primary rubber categories are further divided into subtypes.

People ask for molding compatibility of those subtypes. Worry not! I will discuss each of those rubber types with thor molding compatibility in the section below. So, let’s get started.

1- EPDM

Ethylene Propylene Diene Monomer is a synthetic rubber. Manufacturers used to produce different products through the injection molding process. What makes EPDM stand out is its low viscosity. This means that this material can be quickly filled into molds. Moreover, it is around 150 degrees Celsius, another big plus. You don’t need extremely high temperatures for its melting.

2- Butyl Rubber

This synthetic rubber also undergoes injection molding. It has low permeability to gases, which is a big drawback. Manufacturers generally don’t injection mold this rubber. Moreover, it has a slow curing rate. This means that the solidification of butyl rubber takes more time. Its usage in the injection molding process would make it sluggish. Therefore, manufacturers typically don’t prefer using it in the molding process.

3- Nitrile Butadiene Rubber (NBR)

This rubber is one of the most popular materials for injection molding. It has excellent fluidity characteristics. This allows it to be filled into molds quickly. Moreover, this rubber has a high curing rate, another big plus. This indicates that solidification of the molten form of this material is also easy. The final products made with NBR are robust, durable, and elastic.

4- Styrene-butadiene Rubber (SBR)

This rubber has many valuable properties. For example, it has high tensile strength, high abrasive resistance, and elasticity. Above all, it is available at a very affordable price compared to other types. All these features make it a lucrative option for manufacturers to injection mold it. But the question is: Can SBR injection be molded? The answer is Yes! It can be quickly melted and filled in the molds for the molding process.

5- Liquid Silicone Rubber (LSR)

Liquid silicone rubber is a popular option for injection molding. The reason is that it is present in liquid form. So, it does not pose any challenge when filling it into molds. Moreover, heating this material is straightforward. The heating process further reduces the viscosity of this material. Products made with this rubber material show excellent mechanical strength.

What I like about LSR is that it flows easily. This allows you to quickly fill any complex or intricate mold cavity. It makes it possible to create products with highly detailed designs. Moreover, these products would be strong and durable. However, the injection molding of LSR is a bit different from that of other rubber types.

6- Natural Rubber

All the natural rubbers can be injection molded. It means they can be used to make different products using molds. However, different types of natural rubbers require different temperatures and pressure settings. Moreover, at high temperatures, this rubber can deteriorate in its quality.

Therefore, proper temperature and pressure adjustment is critical. During use, note the exact melting point of specific natural rubber. Heating these types of rubber at extremely high temperatures would affect their equity. Different additives are added to achieve the desired properties while using natural rubbers.

Quick Highlight: Almost all types of rubbers can be injection molded. However, their ease of molding can vary depending on their properties. In the section above, I’ve listed the most popular rubber types. Manufacturers use them extensively in the injection molding process. The molding of these types helps make solid and durable rubber products.

Frequently Asked Questions

Can I inject molding butyl rubber?

Yes, butyl rubber can undergo an injection molding process. Manufacturers use it to make products of desired characteristics. However, this rubber is not ideal for molding due to its low permeability to gasses. However, manufacturers use it in molding if needed.

Can you inject mold EPDM?

Yes, these synthetic rubbers can easily inject mold. Their melting point is not too high, and their curing rate is high, which speeds up the molding process.

Can natural rubber be injection molded?

Yes, natural rubbers can be injection molded with ease. However, their injection molding requires a specific and controlled temperature. They are sensitive to heat. Over or extreme heating would deteriorate their quality.

Can silicone rubber be injection molded?

Yes, silicon is a synthetic rubber and one of the most popular options for molding. It offers excellent resilience and strength. However, its molding is different as it is present in a liquid state.

Does injection molding of different rubbers require the same parameters?

No, different rubbers require different parameters, such as temperature and pressure. Some have high melting points, while others have low melting points. So, correct adjustment of those parameters is paramount.

What types of rubber can be injection molded?

There are different types of rubber available. Each can be injection molded, but it requires specific parameter settings. Both natural and synthetic rubbers can undergo injection molding with ease.

Conclusion

There are two types of injection molding machines. One of those is dedicated to molding rubber. This indicates that the rubber material is very suitable for molding. People who say rubber is unfit for molding are wrong. There are two main types of rubber: natural and synthetic rubber. Both of these two primary types have further divisions.

However, all of them can be injection molded. However, their processing requires specific parameters such as temperature and pressure. Remember, some rubbers have low melting points while others can have high ones. So, their heat should be done according to their melting point. Exceeding their melting point would affect their quality.