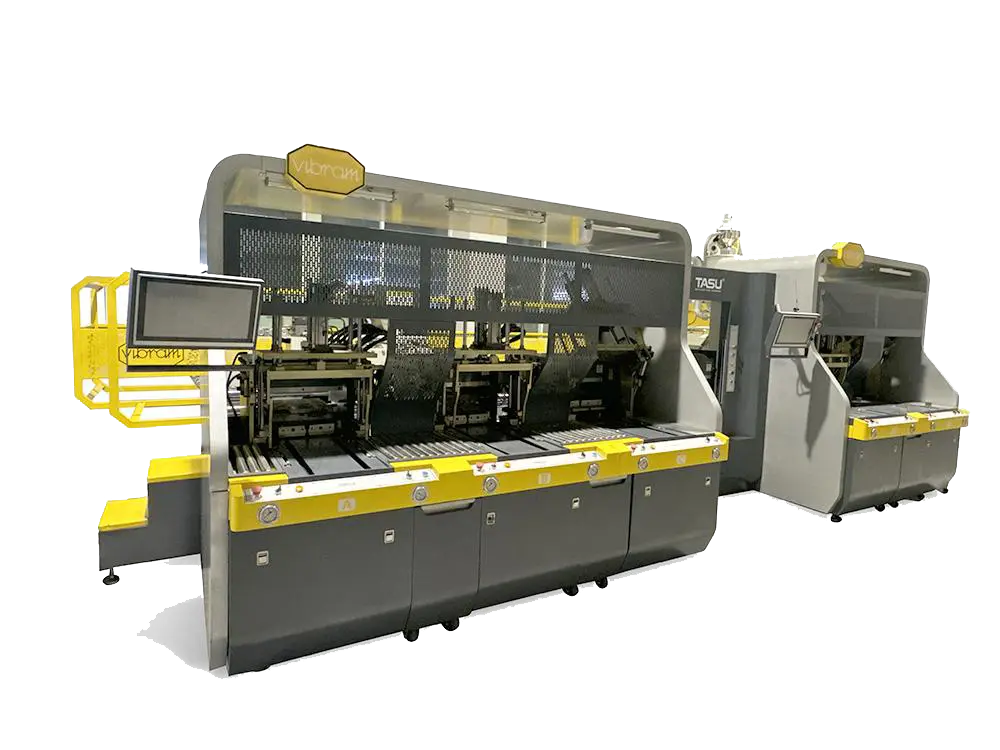

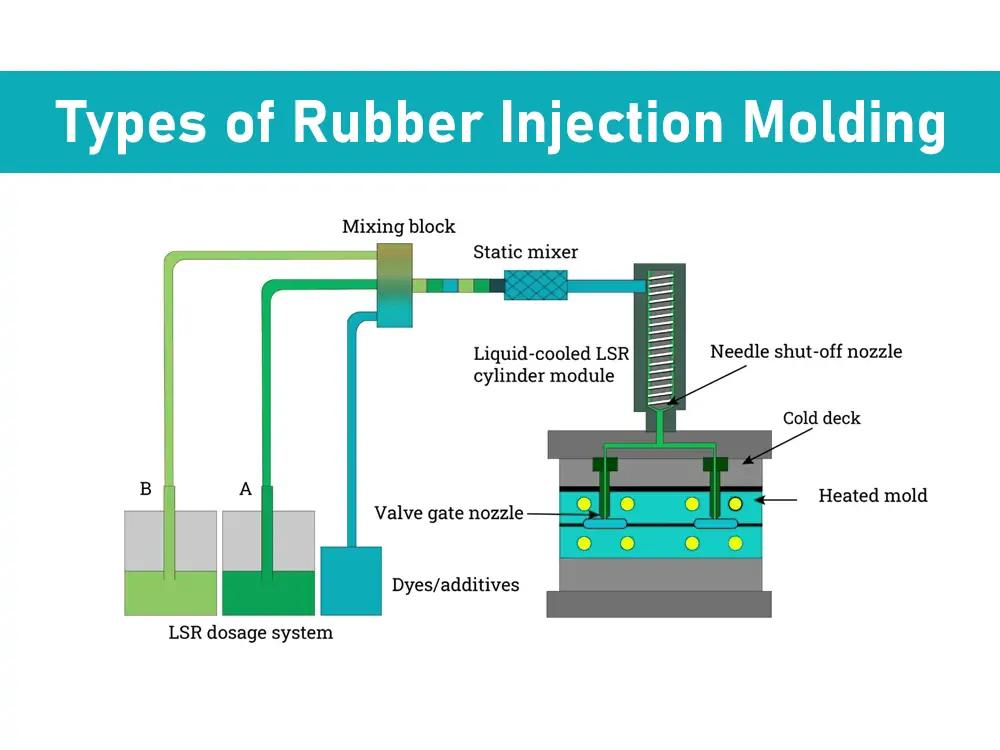

Your Trusted Rubber Injection Molding Machine Manufacturer – TSAU

DONGGUAN TASU INDUSTRIAL CO., LTD is a advanced manufacturer of fully automatic rubber injection molding machines. Over the years, TASU people have made remarkable progress in the field of rubber injection molding machines through years of continuous efforts and experience. In the research and development of “rubber automatic injection molding machine” in the field of major breakthroughs, now the equipment is not only applicable to the rubber industry in many fields, but also in the material frontier end-market and the strong combination of customers, to provide equipment + material + process of the full set of system solutions; our pursuit of excellence, professional customization capabilities, so that we and many well-known companies around the world to establish a strategic partnership, which includes Vibram, Timberland, CAT, PUMA, UGG, Clarks, Crocs, and BELLE, and their cooperation not only represents our strength, but also our commitment to help customers maximize the value of the effective commitment, TASU is committed to become a top rubber injection molding machine solutions provider, at the same time, continue to move towards the world’s leading brand of rubber injection molding technology to continue to work hard.